In this blog post, I modified a cheap buck converter module to add a brightness control, and used it to drive a relatively low power strip of cool white LEDs.

I was never a big fan of the cool white LEDs I had ordered the first time round, and Chinese LED strip tech had also come some way since I did that first installation, so I thought it would be a good opportunity to upgrade to some 24V Chip-on-Board (COB) LED tape in a warmer colour temperature.

The new COB tape is a lot denser than the old surface mount LED tape and has a much higher maximum brightness, but the power requirements have also gone up dramatically if you want to use the full brightness. About 100 watts in fact, from a fixed 24 volt supply, for 20 metres of LED tape.

For this one, I decided that due to those requirements, it would be more efficient to adjust the switch mode power supply directly instead of adding an extra output stage like last time. The candidate for the mod was this chunky 120W power supply:

Sadly, this power supply didn’t have an internal trimmer pot, so it wasn’t a simple case of replacing that with an off-board pot. On the upside, the low voltage and mains sections were well separated, but of course extreme caution should always be used when working on a device like this and you should avoid carrying out any work on it while it is plugged in.

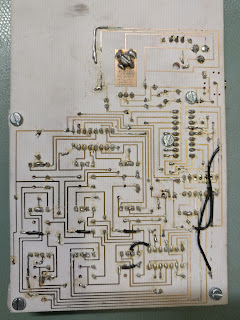

Like with the buck module from part 1, the objective was to add some control over the feedback circuit. I examined the PCB and determined that the core of the feedback circuit in this power supply is the 8-pin IC in the photo below, which is a TSM103WAIDT dual op-amp with built in 2.5V reference. Just like with the buck modules, there is a resistive potential divider and the circuit tries to make the output of the potential divider equal the reference voltage of 2.5V in this case.

This area of the circuit looks quite complex; I believe it also implements overcurrent protection and overvoltage protection, but I didn't take the trouble to trace it all out.

Original feedback circuit resistors:

24.9k high side

2.87k low side

2.50V output from 24V input

I played around with the values in the same spreadsheet from before…

…and eventually arrived at the following configuration: I changed the high side to 10K + 7.5k in series, and retained the original 2.87k on low side, but added a 6.8k fixed resistor and 22k pot series combination in parallel with the 2.87k. New output range 19.26V to 24.17V.

Here’s a short video of the modified power supply in operation:

I somehow damaged the op-amp during my experimentation and had to replace it. Fortunately it was still made after all this time, but the op-amp is end of life now.

With a hole drilled in the case for the pot and a knob fitted, it looks very professional!

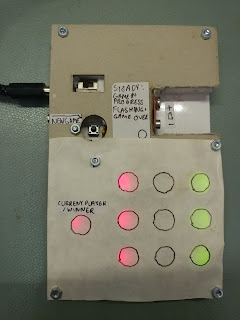

The dimming control works well with the LED light strips. This power supply doesn't seem to give a stable output voltage at very low loads, as it seems to have a discontinuous switching mode to save power when the original load (computer monitor) was in standby; this causes the LED strips to blink a few times a second when the brightness is turned all the way down. In the final installation, the large dot matrix clock is also powered from the power supply output (it has its own buck converter to generate its 5V power supply so adjusting the supply voltage doesn't affect it) and this additional load prevents the blinking from happening.